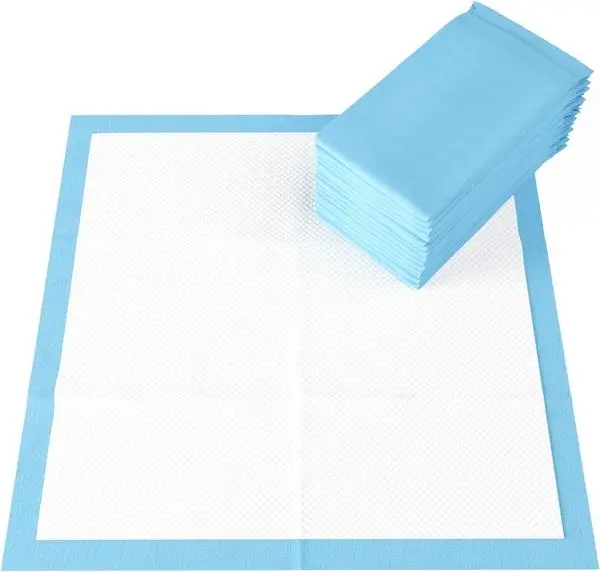

In the global healthcare market, the disposable underpad exporter is not only related to the economic interests of enterprises, but also bears the responsibility for medical safety and patient health. Therefore, disposable underpad exporter must ensure the excellence and stability of product quality. This article will explore how disposable underpad exporter can implement a full range of quality assurance measures.

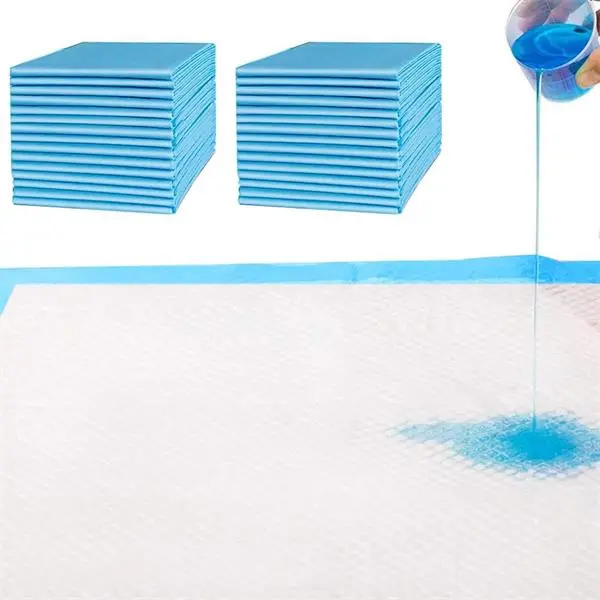

The quality of disposable underpad first depends on the choice of raw materials. High quality raw materials are the basis for producing high quality products. Disposable underpad exporter should establish long-term cooperative relations with reputable suppliers to ensure the stable and reliable quality of raw materials. In addition, regular quality testing and evaluation of raw materials to ensure that they comply with relevant standards and regulations is a key link to ensure product quality.

The production process of disposable gaskets involves several links, each of which may have an impact on product quality. Therefore, disposable underpad exporter need to establish a strict production process quality control system. This includes the development of detailed production processes and operating specifications to ensure that employees operate in accordance with the specifications; Carry out regular maintenance and inspection of production equipment to ensure its normal operation; Critical control points in the production process are monitored and recorded in real time to identify problems and take corrective action.

Quality inspection is an important link to ensure the quality of disposable gaskets. Disposable underpad exporter should establish a sound quality inspection system and conduct a comprehensive quality inspection for each batch of products. This includes appearance inspection, size measurement, physical performance testing, chemical performance testing and many other aspects. Only through strict quality testing can we ensure that the products meet the relevant standards and regulations and meet the needs and expectations of customers.

Disposable underpad exporter should always pay attention to the needs and feedback of their customers and constantly improve the quality of their products and services. Through the collection and analysis of customer feedback, find the existing problems and shortcomings of products, develop improvement measures and put them into practice. At the same time, to provide customers with quality after-sales service, answer customer questions, deal with customer complaints, to ensure the continuous improvement of customer satisfaction.

In short, disposable underpad exporter needs to implement a full range of quality assurance measures, from the source control of raw material quality, to the quality control of the production process, to strict quality testing and continuous improvement and customer service, each link needs to be carefully controlled. Only in this way can we ensure the excellent quality and stability of the disposable liner, and win the trust of customers and the recognition of the market.