Medical product development is one of the most complex manufacturing processes, with strict requirements and quality standards. The development cycle of any medical product involves several unique stages to ensure effective and safe production. These phases range from concept development to medical product design, prototyping, testing, validation and validation, and mass production. The specific research and development process of WILLCOME is divided into the following stages:

1. Conception, conceptualization, and risk analysis (1-1 month)

2. Development, regulatory compliance (6-12 months)

3. Design development, Verification and Validation (6-12 months)

4. Manufacturing and Testing (6-12 months)

5. Clinical trials and approval (1-3 years)

6. Launch and postmarketing activities(Keep underway)

Spunbonded polypropylene (PPSB)

Spunbonded polypropylene is a lightweight, breathable fabric, which is consist of continuous filament, with good tensile strength and elongation

Features

1. Standard fabric for non-toxic workplace,grimy-work environment applications.

2. Low-cost solution for protecting workers in dirty environments

3. Different colors are available

Applications

In most industry, hygiene and medical fields for basic protection, such as lab coats, coveralls, shoe covers, face masks, Isolation gowns, surgical gowns, surgical caps, patient bed sheets, etc

Spunlace non-woven is an environmental friendly fabric. Without additional chemical, spunlace non-woven is done by high pressure water entanglement to form all the web.

Features

1. Great permeability, absorbent, durable, and linting-free

2. Material with nice strength, smooth formulation and soft touch

3. Easy to sew or wash

Applications

Widely apply to different commercial, health care, medical, industrial areas, such as disposable clothes, bed sheets, doctor caps, cooking towels, factory cleaning wipes and other customer goods.

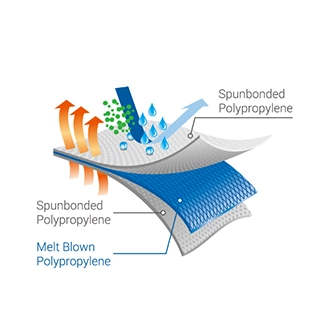

Spunbonded Meltblown Spunbonded (SMS)

SMS is a tri-laminated and comprised of layers of spunbond polypropylene, meltblown polypropylene, and spunbond polypropylene. Spunbond layer is with good tensile strength and elongation, Melt blown layer is consist of continuous micro fiber.

Features

1. Fluid and particulate barrier.

2. Strong and durable, yet offer outstanding comfort, breathability, softness, and wearability.

3. Lightweight and resistant to tears and punctures.

Applications

Widely apply to high class protection area of medical, industrial, laboratory, electronical, pharmaceutical, such as isolation gowns, patient gowns, lab coats, coveralls, procedure gowns, caps and face masks, boot covers, aprons, napkins and diapers.

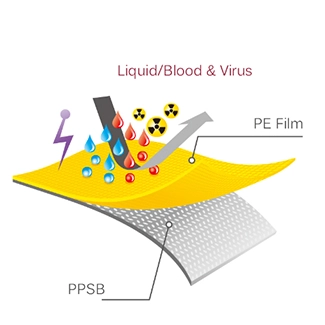

Polyethylene Coated Polypropylene (PP+PE)

Spunbond polypropylene is coated with a layer of impervious polyethylene.

Features

Coated with PE film, has provided great waterproof performance and impervious character.

Applications

Widely used for high level of fluid resistant area, to protect from liquid chemicals or biological hazards. For example: isolation gown, surgical gowns, bed sheet, sleeve cover, etc.

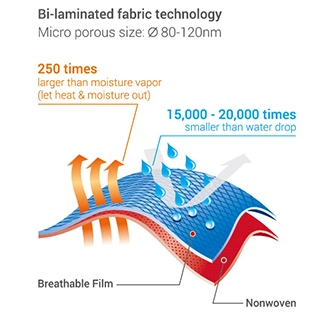

Composed by PPSB laminated breathable PE film which is developed by Derekduck. Different color with different weight composition could be customized.

Features

ASTM F1670 for anti blood penetration certified. > Passes EN1149-5 for antistatic test.

Applications

Widely apply to protection area of medical, industrial, laboratory, electronic, pharmaceutical, such as isolation gowns, patient gowns, lab coats, coveralls, procedure gowns, hoods, boot covers, aprons, napkins and diapers, rainwears, car covers, pillow protectors, and mattress protectors.